ENDORSED BY THE LEADING EXPERTS,

NATALIYA DOLENKO GENÈVE SA, Switzerland

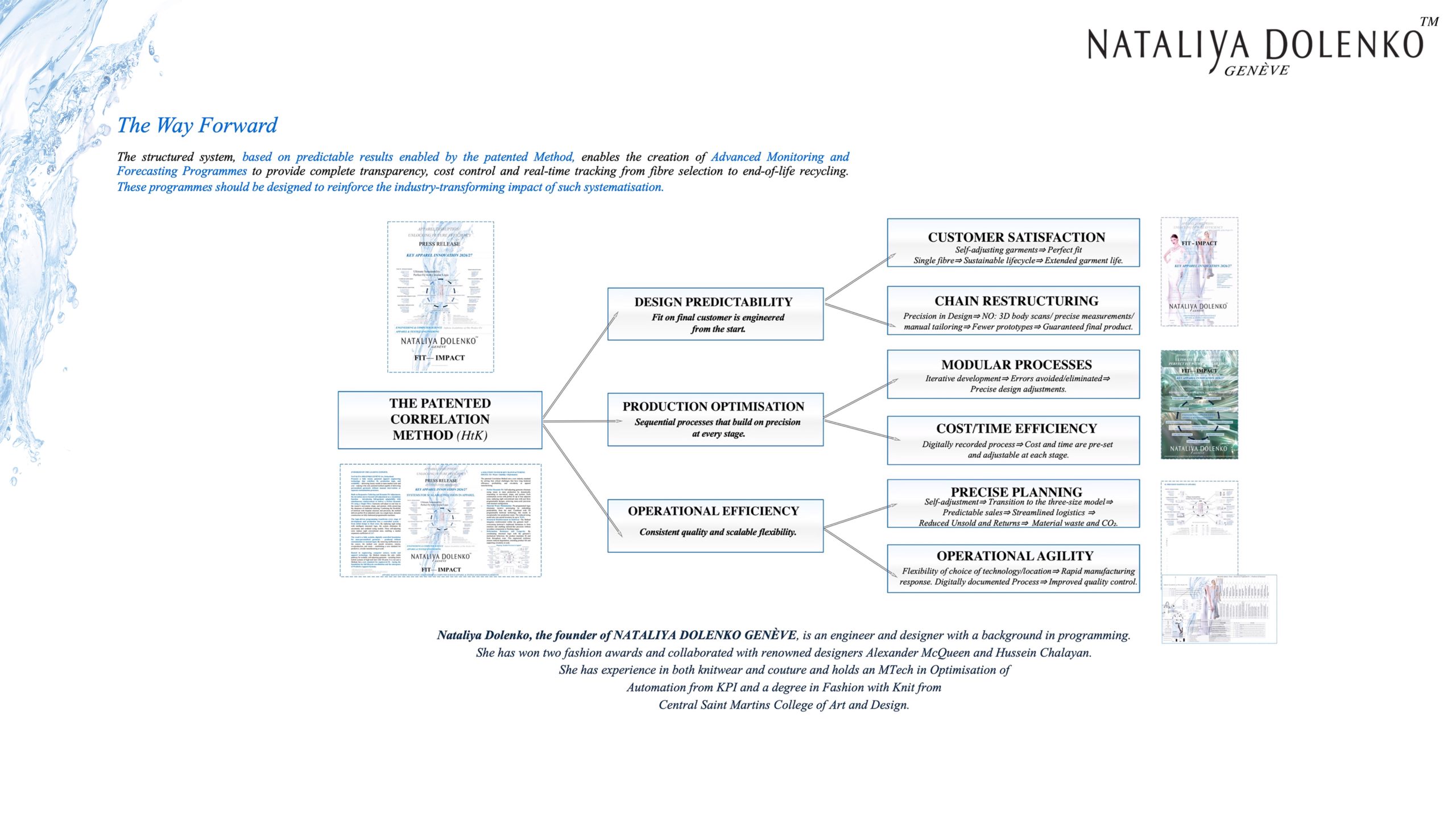

Presents a fully tested, patented apparel engineering technology that redefines fit, production logic, and scalability – delivering luxury results at mass-market scale and cost –making it the only patented method capable of delivering personalised garments without manual intervention or separate customisation processes.

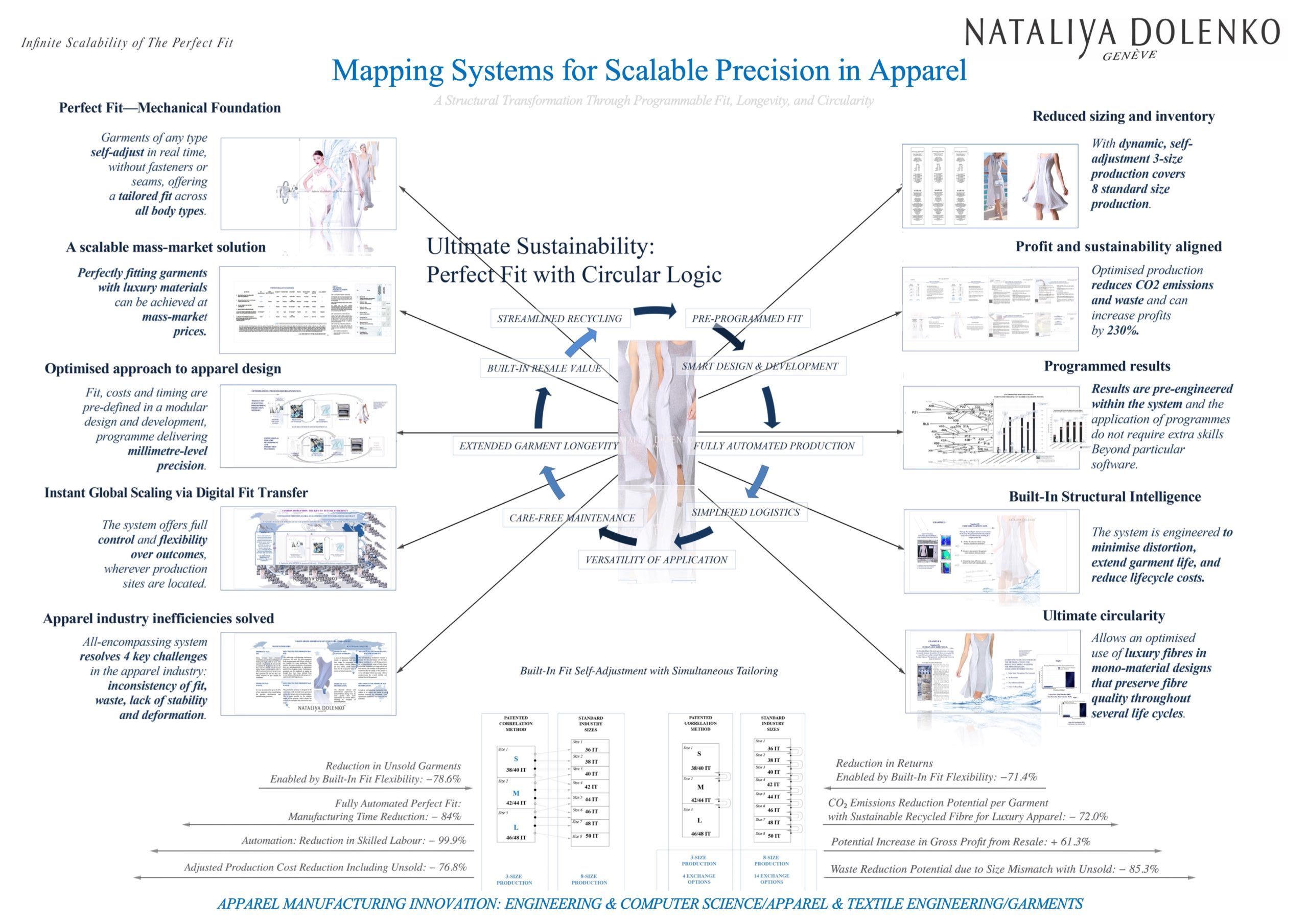

Built on Responsive Tailoring and Dynamic Fit Adjustment, the invention moves beyond self-adjustment as a standalone function introducing full-garment adaptability with simultaneous reinforcement to deliver a Perfect Dynamic Fit using a Single Fibre. Garments self-adjust in real time to the wearer’s movement, shape, and posture, while preserving the sharpness of traditional tailoring. Combining the flexibility of knitwear with bespoke structure and precision, the method delivers perfect fit at industrial scale via a single-layer, dynamic construction on fully-fashioned programmable machines.

The logic-driven programming transforms every stage of development and production into a controlled system from initial design to final reuse. By replacing rigid sizing with intelligent structural logic, the system eliminates fit uncertainty and outdated sizing models. Three self-adjusting sizes replace eight conventional ones, enabling a market expansion coefficient of 2.67.

The result is a fully scalable, digitally controlled foundation for mass-personalised garments produced without customisation or manual input. By removing inefficiencies at the source, the method cuts unsold inventory, returns, overproduction, and waste establishing a new standard for predictive, circular manufacturing at scale.

Rooted in engineering, computer science, textile and apparel technology, the Method remains the only viable pathway for scalable, self-adjusting garments – including future hybrid systems of high-tech knit with 3D print. It is not just a Method, but a new standard for engineered fit – laying the foundation for full lifecycle coordination and the emergence of Predictive Apparel Systems.

A SOLUTION TO FOUR KEY

MANUFACTURING ISSUES:

-

FIT

-

Waste

-

Stability

-

Deformation

The patented Correlation Method sets a new industry standard by solving four critical challenges that have long hindered efficiency, profitability, circularity in apparel manufacturing.

-

Perfect Dynamic FIT: Self-adjusting garments eliminate sizing issues in mass production by dynamically responding to movement, shape, and posture. Each construction covers with perfect fit up to four adjacent sizes, replacing eight conventional ones with just three programmable designs, achieving mass-scale precision with minimal configuration

-

Material Waste Minimisation: Pre-programmed logic eliminates iterative prototyping by embedding predictability from the start. Combined with 3D programmable knitwear technology, this results in exceptionally low production waste. The reduced sizing model also cuts unsold inventory by up to 78.6%.

-

Structural Reinforcement in Knitwear: The Method integrates reinforcement within the garment itself overcoming knitwear’s traditional limitations in form retention and enabling tailored-like precision without secondary components or finishing stages.

-

Deformation Resistance and Longevity: By coordinating structural logic with the garment’s mechanical behaviour, the product maintains fit and form throughout wear. This engineered resilience ensures reduced degradation, extending product life and supporting circularity at scale.

Geneva, Switzerland September 2025